Krausz USA is proud to introduce its new wide-range HYMAX2 Coupling, the next-generation HYMAX.

INSTALLATION MANUAL. THIS PRODUCT IS TO BE INSTALLED AND SERVICED BY A TRAINED GATE SYSTEMS TECHNICIAN ONLY. This model is for use on vehicular passage gates ONLY and not intended for use on pedestrian passage gates. This model is intended for use in Class I, II, III and IV vehicular slide gate applications. You must be trained on SARA 3000, and any accessories, as well as its functions and controls. If you require assistan ce in the setting up, use or maintenance of the SARA 3000, or if you experience any unexpected operation while using it, please contact your local ArjoHuntleigh office. A list is given inside the back cover of this manual. Operating Manual and Inspection Book SMART LIFT 2.30 SL, 2.35 SL, 2.40 SL / HYMAX S 3000, 3500, 405 OPI 7 Version 1.0 After successful set up, complete this form fully, sign it, make a copy and send the original to the.

Used for section replacement, HYMAX2 connects two pipes of the same or different OD pipes and materials, up to 1.3” range.

HYMAX 2 is based on the original game-changing HYMAX that has been field-proven in millions of installations in the US:

- HYMAX 2’s patented flip gasket can be easily flipped in or out to accommodate different pipe OD’s

- Advanced no-tear gasket technology for maximum installation efficiency

- Only 2 top-facing bolts = faster, easier, safer installation

- Dynamic deflection of 4° per side – reducing future pipe damage

- Suitable for all types of pipes – ductile iron, cast iron, steel, copper, PE, PVC, AC, GRP

Product performance, OD range and pressures are identical to those of the original Hymax

Just flip the No-tear gasket from the inside out to accommodate larger OD pipes.

Closed gasket position Flip the gasket for wider range

Hymax Lifts 3000 Manual Free

See Product Promotion Video

For HYMAX product specification sheets and product installation instructions, click the download links on this page.

Want your team to learn more about new HYMAX 2? Order a Lunch N’ Learn free educational session at your location.

For more information about our products, please contact KRAUSZ USA or your regional Krausz sales manager.

SIZES 2″ to 12″

FAST AND EASY INSTALLATION

- Easy flipping of the gasket allows Hymax 2 to accommodate wider diameter pipe.

- Lightweight construction enables fast and easy installation, with minimum manpower, reducing time in the ditch and improving worker safety.

- Hymax 2 two-bolt coupling's unique top-facing bolts enable easy installation access.

- Ready-to-use, stab-on design eliminates the need for extensive under-pipe digging and work.

MULTIPLE APPLICATIONS

- Broad variety of products, from couplings to flange adaptors and reducers.

- Extensive portfolio of products with 4” - 12” nominal pipe size.

- All products work with a variety of materials: ductile iron, cast iron, steel, copper, PE, PVC, AC, and GRP.

- One single product can connect pipes of two different materials, allowing transition capability of up to 2.1”

FLEXIBLE CONNECTION

Hymax Lifts 3000 Manual Online

- During installation, allows for up to 4° angular deflection on each end, as well as for misaligned pipes.

- Absorbs post-installation dynamic pipe deflection of up to 4° on each end, reducing the risk of damage and cracking due to ground shifts and temperature changes.

- Adapts to out-of-round pipe shape, for optimum fit on both ends.

HIGH DURABILITY

- High-quality sealing solution – Patented hydraulically assisted gasket features two-stage sealing: mechanical sealing that is effective under vacuum or non-pressure; and self-inflated gasket using water pressure.

- Working temperature: -20°F to +125°F.

- Fusion-bonded epoxy coating enables an insulated product and prevents corrosion.

- Nuts, bolts and other components are made of stainless steel.

- Innovative radial closing design and sealing systems eliminate installation errors.

- Advanced Molecular Anti-Galling (MAG) unique dry treatment process on nuts and bolts, based on embedded zinc, preventing galling and enabling repeated bolt tightening; it also eliminates the need for grease, preventing dust and dirt build-up.

- One-piece design delivers fortified strength and enhanced flexibility.

COST-SAVING

- Hymax 2 suits a wide range of pipe diameters, replacing the need to use dedicated-range products and thus reducing inventory costs and saving shelf space.

- Fast and easy installation saves time and money.

Hymax Lift S 3000 Manual Treadmill

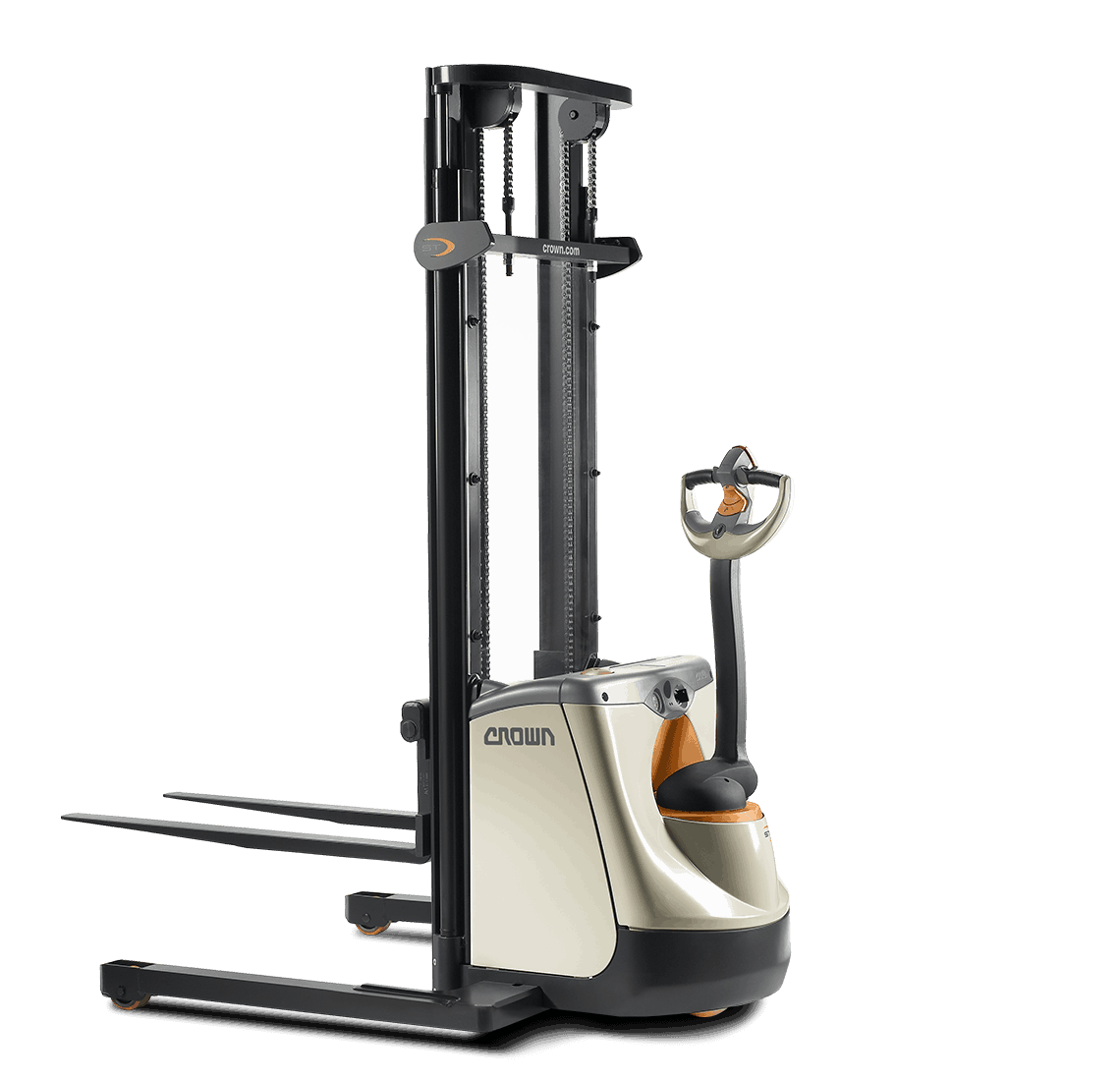

Push Stacker Overview

Manually pushed walk behind straddle stackers are used in a variety of material handling applications in which a full sized fork lift is either not economically viable or practical for the amount of lifting or traveling the application calls for. Straddle stackers are also used in areas where a tight turning radius is required or as mobile work positioners for extended periods of time. All the manually pushed models we offer are ideal solutions for the occasional loading and unloading of semi-trucks. If your application calls for frequent travel or occasional travel longer than a hundred feet, we recommend a powered straddle stacker especially when dealing with loads in excess of 2,000 lbs.

The MXSA is a manually pumped up straddle stacker. It is an economic solution for those applications that occasionally need to load, unload and stack a couple pallets. The MXSA also works well as a mobile work positioner in applications where the height adjustments are either minor or only occur occasionally.

The MMSE is the electric lift, adjustable fork version of the MMS. It uses the same design of lift system but replaces the manual foot pump with an electrically driven motor. It has a built-in automatic charger and cord, key switch, BDI and charging status lights. An optional slide-on platform is available.

Hymax Lifts 3000 Manual 2017

The MXIBH is a heavy duty built-to-order straddle stacker suitable for the most demanding industrial applications. These units are built to last and are commonly passed down from one generation to the next. Their simple yet strong design excels at positioning loads throughout the work day within the confines of a small sized warehouse. Numerous standard and custom options are available.